AG Autogenous Grinding Mineral Processing

Metallurgical ContentIntermediate Autogenous GrindingAutogenous Grinding ExplainedTest ConditionsGrinding Characteristics of Short Mill Other articles where autogenous mill is discussed: mineral processing: Grinding: Autogenous mills operate without grinding bodies; instead, the coarser part of the ore simply grinds itself and the smaller fractions To semiautogenous mills (which have become widespread), 5 to 10 percent grinding bodies (usually metal spheres) are addedautogenous mill Britannica The AG/SAG mills generally receive ore directly from the crushing plants with alternative arrangements made to receive ore from a stockpile In rare cases, the feed is directly from the mine Schematic diagrams of a typical semiautogenous mill with large D/L ratio and a square mill are illustrated in Figure 91, Figure 92Autogenous and SemiAutogenous Mills ScienceDirect

AG SAG Mill for Mineral Processing Wet Aerofall SAG

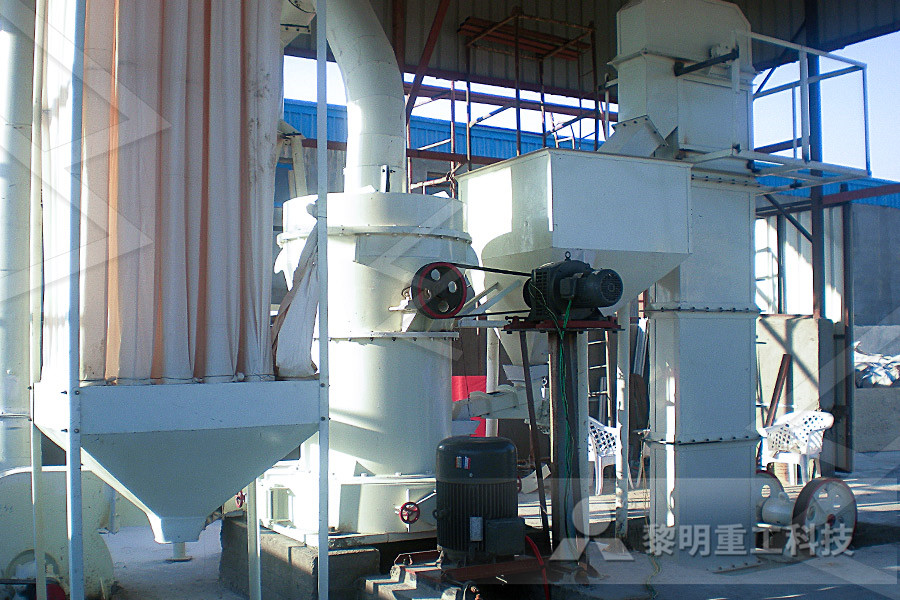

AG mill (autogenous mill) is a mediumfree mineral grinding equipment The raw ore and the coarsely crushed ore are directly fed into the AG mill No other medium is involved in grinding Only the impact between the ore is used for selfgrinding The ore larger than 100mm in the AG mill plays the role of grinding mediumAn autogenous mill of ID 67 m and an effective grinding length of 21 m was fed with ore of SG 38 to 20% of its volume The mill was operated continuously 24 hours per day at 1200 t per day and 75% of the critical speedThe solids in the mill charge were at 80% solids Estimate:1 The power consumption per tonne per daySemi Autogenous Grinding Mill an overview Autogenous Grinding Mining Fundamentals Autogenous grinding is a process of grinding ore in a rotating cylinder, using large pieces of the same ore Autogenous mills operate mechanically like ball mills; however, the media used for grinding differs Simply put, in autogenous grinding, the media is also the material that is being ground Autogenous Grinding Mining Fundamentals

Processing Citic Pacific Mining

Every 24 hours, around 180,000 tonnes of ore are fed into the six milling lines’ autogenous grinding mills (AG mills), which are the largest grinding mills in the world Each mill measures about 12m in diameter and has an internal volume of 1,220 cubic metres As the AG mill turns, the ore crushes against itself and breaks apart 关于STM32的串口溢出中断,之前在网上看过两篇博客《STM32串口接收中断溢出问题解决》和《STM32 串口中的硬件BUG,请注意!》,也是从中学习到了串口ERROR的用法。关于串口溢出中断的相关寄存器操作和一些细节,两位博主已经讲得很 STM32串口使用心得(二)——串口溢出中断(ORE In the Autogenous mill ore is broken up by collisions with itself, and in the Ball mill, by collisions with steel balls Motoring along: how to select the best Autogenous mill Article about autogenous mill by The

AG SAG Mill for Mineral Processing Wet Aerofall SAG

AG mill (autogenous mill) is a mediumfree mineral grinding equipment The raw ore and the coarsely crushed ore are directly fed into the AG mill No other medium is involved in grinding Only the impact between the ore is used for selfgrinding The ore larger than 100mm in the AG mill plays the role of grinding mediumSince the early 1980s, we have been designing and manufacturing Semi Autogenous Mill (SAG Mill) and Autogenous Mill (AG Mill) under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only SAG and AG Mills operate by lifting ore/grinding media and dropping it on SAG Mill Autogenous and SemiAutogenous Mills "IntroductionIn autogenous mills, grinding of the ore feed is accomplished by the direct action of the variously sized rocks making up the feed on each other and the mill interior Size reduction is achieved without the addition of grinding media foreign to the mill feed, differing in this respect from rod, ball, and pebble millingAutogenous and semiautogenous mill circuits

The Modelling of Autogenous and Semiautogenous Mills

regardless of the mill and ore being treated This greatly simpli fies the task of determining the rate at which breakage events are generated However in sag mills and in partcular ag mills the grinding media derive from the feed ore The feed ore hardness and size distribution therefore dictate the number and size distri primary crushed ore and 34% lower than for autogenous grinding of primary crushed ore Subsequently, pilotscale primary grinding tests were performed in Minnesota on the magnetic taconite ironore as part of an overall effort to develop a concentrating process to produce an ironore concentrate containing less than 17% silicaAUTOGENOUS MILL FEED PREPARATION TO REDUCE autogenous mill for silver ore high output high efficiency rod grinder mill the rods used in the mill usually a high carbon steel can vary in both the length and the diameter however the smaller the rods the larger is the total surface area and hence the greater the grinding efficiency autogenous mill autogenous or autogenic mills are so autogenous mill for silver ore high output

Case Boliden Autogenous Mill Application

An autogenous mill is a mission critical application found in the concentrator section of a mine The mill’s primary task is to grind ore into a suitable size for the next step in the concentration process There are many different types of mills; ball mills, rod mills, SAG (SemiAutogenous Grinding) and autogenous mills Autogenous mills are de ned by the ore being the only source of grinding media and the absence of a secondary media such as steel The circuit is operated in a closed loop with a horizontal vibrating screen tted with 630 m polyurethane classi cation panels The Bene ts of Optimisation and Model Predictive Control on 青岛海洋研究设备服务有限公司成立于1986年,是集海洋调查、探测技术、海洋工程、水道测量、环境监测和保护等海洋仪器引进与开发、技术咨询、技术服务、系统集成于一体的综合性高科技企业。自成立近三十年以来, 公司以其雄厚的技术实力, 良好的市场信誉, 在诸多重大项目上取得了令人信服 青岛海洋研究设备服务有限公司

autogenous mill Britannica

Other articles where autogenous mill is discussed: mineral processing: Grinding: Autogenous mills operate without grinding bodies; instead, the coarser part of the ore simply grinds itself and the smaller fractions To semiautogenous mills (which have become widespread), 5 to 10 percent grinding bodies (usually metal spheres) are addedAutogenous Mill is a new type of grinding equipment which has functions of crushing and grinding Its working principle is basically the same as that of ball mill Ore itself is the medium, through mutual impact and grinding to achieve ore grinding The cylinder has a larger diameterAutogenous Mill qxdali autogenous mill for silver ore high output high efficiency rod grinder mill the rods used in the mill usually a high carbon steel can vary in both the length and the diameter however the smaller the rods the larger is the total surface area and hence the greater the grinding efficiency autogenous mill autogenous or autogenic mills are so autogenous mill for silver ore high output

SAG Mill Autogenous and SemiAutogenous Mills

Since the early 1980s, we have been designing and manufacturing Semi Autogenous Mill (SAG Mill) and Autogenous Mill (AG Mill) under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only SAG and AG Mills operate by lifting ore/grinding media and dropping it on Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mill Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable particle size In Vietnam iron ore dressing plant, the ore capacity is Autogenous Mill mxinhaiepcregardless of the mill and ore being treated This greatly simpli fies the task of determining the rate at which breakage events are generated However in sag mills and in partcular ag mills the grinding media derive from the feed ore The feed ore hardness and size distribution therefore dictate the number and size distriThe Modelling of Autogenous and Semiautogenous Mills

Processing Citic Pacific Mining

Every 24 hours, around 180,000 tonnes of ore are fed into the six milling lines’ autogenous grinding mills (AG mills), which are the largest grinding mills in the world Each mill measures about 12m in diameter and has an internal volume of 1,220 cubic metres As the AG mill turns, the ore crushes against itself and breaks apart An autogenous mill is a mission critical application found in the concentrator section of a mine The mill’s primary task is to grind ore into a suitable size for the next step in the concentration process There are many different types of mills; ball mills, rod mills, SAG (SemiAutogenous Grinding) and autogenous millsCase Boliden Autogenous Mill Application 98 3 Autogenous and semiautogenous mills 3 Ball mills 3 Rod mills 3 Scrubbers 3 Lime slaking machines Wet grinding Dry grinding 3 AEROFALL mills 3 Ball mills , iron ore and other mineral materials The mill shells are delivered as a single unit or split into several parts Largediameter mill shells are transported to the plant site in Industrial Solutions Autogenous, ThyssenKrupp

青岛海洋研究设备服务有限公司

青岛海洋研究设备服务有限公司成立于1986年,是集海洋调查、探测技术、海洋工程、水道测量、环境监测和保护等海洋仪器引进与开发、技术咨询、技术服务、系统集成于一体的综合性高科技企业。自成立近三十年以来, 公司以其雄厚的技术实力, 良好的市场信誉, 在诸多重大项目上取得了令人信服

- molino martillos roca

- equipos trituradora de piedra utilizada peque 3Fa

- venta de imagen molino bola en Aruba

- Cedar s trituradora de no De Eriales

- sistema de lubricacion chancador

- de pulir y acabado de la máquina

- que venden una trituradora de piedra utilizado

- trabajando karnataka planta trituradora de piedra

- trituradora de rodillos lisos en lombia

- Máquina Fichas Tecnicas de trituradora de Impacto Venta

- Trituradora De Piedra Chinos Proveedores

- trituradora de piedra trituradora n capacidad de

- chancador de rodillo funcione

- de la máquina trituradora de oro en California

- piedra proveedores profesionales

- Mi Viejo Molino Café

- fresadoras verticales usadas en miami florida

- equipo de sidra de manzana usado california

- precio de molino de martillos de hierbas aromaticas en lima

- sto de instalación de planta de molienda de oro

- herramientas de nstruccion para el futuro

- Pc de la serie chancadora de plásti

- proyecto piadora de piedras

- molienda molienda en vivo

- proceso de trituradora de carbón

- machacadora de mandibulas fabricante de la mexi

- proceso vrm en planta de cemento

- trituradoras en ciudad de puebla

- hierro maquina de flotacion de mineral

- trituración machinemanufacter en la India