Cone Crusher Working Principle Animation

Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing The cone crusher consists of a concave that provides the outer surface constraining the particles and a mantle or cone which is inside the concave, see Briggs (1997) and Evertsson (2000) for a Principle of a cone or gyratory crusher The hydraulic cone crusher handles secondary crushing in the production line, and specializes in processing of mediumhard materials During the operation of the equipment, there will be problems such as tooth cracking, wear, jamming, and undercutting of the umbrella teeth, which will not only affect production, but also Cause direct or indirect economic lossesCrushing Principle, Gear Wear and Solution of Cone

Cone crusher basics in 4 minutes — SRP

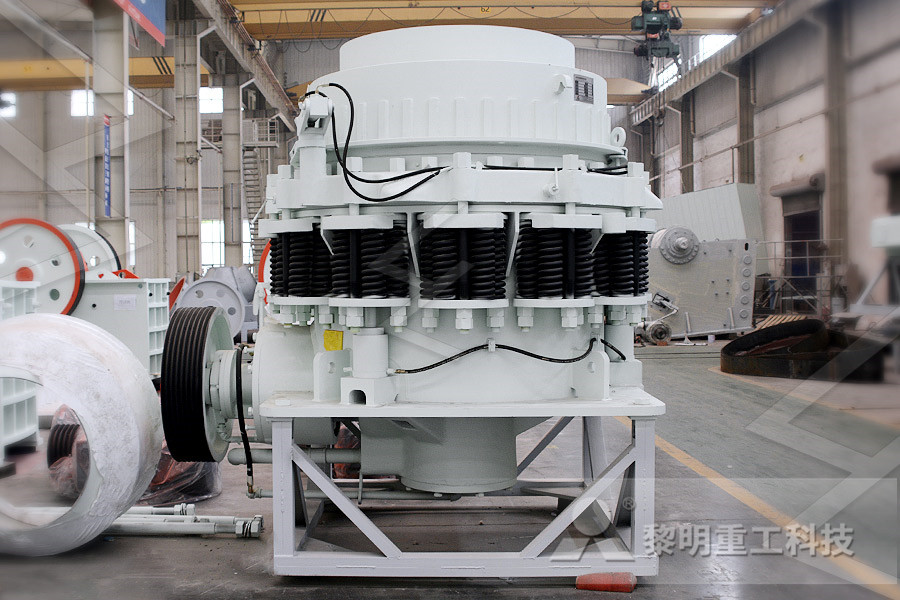

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushingThe cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct driveCone Crusher an overview ScienceDirect Topics Understanding the Cone Crusher The first step in learning how to adjust a cone crusher is understanding the principles in place that allow the cone crusher to do its job Based on the diagram above, we can identify the main parts of a cone crusher: the feed opening, the concaves, the mantle and the sizing gapA Detailed Overview of Cone Crushers and What You

Cone Crusher – Conmix Crusher

Cone Crusher is simplicity of design and rugged construction has made for ideal crushing operations by Shree Conmix Engineers Pvt Ltd For the most efficient and economical production, a wider range of Conmix Cone Crusher models are available for you yo choose from The Cone Crusher has remarkable high nominal effective stroke and cavity range, which really Operating Principal • In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber • The relative amounts of IPB and SPB depends on factors like chamber design, crusher geometry, speed, Crushing Principles of Mechanical CrushingA Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the Cone Crushers McLanahan

® HP Series™ cone crushers Outotec

Crusher automation Outotec IC70C™ is a crusher automation system that further improves the operation of your ® HP™ crusher Using it can increase your production by more than 10% With Outotec IC70C™ you can control maintenance, setting modifications, production followup and data extractionThe cone crusher consists of a concave that provides the outer surface constraining the particles and a mantle or cone which is inside the concave, see Briggs (1997) and Evertsson (2000) for a Principle of a cone or gyratory crusher cone crusher,spring cone crusher,cone crusher working principle Spring Cone Crusher Working Principle Driven by the electricmotor ,the eccentric shaft bush will rotate with the triangle belt,small and big bevel gear,big bear Cone Crusher Principle Crusher Mills, Cone Crusher, Jaw

Working Priniciple Of Cone Crusher

What Is A Hydraulic Cone Crusher HongXing Machinery Dec 05 2019 Hydraulic cone crusher working principle When the cone crusher works the rotation of the motor is performed by a pulley or coupling the cone crusher transmission shaft and the crusher cone under the force of an eccentric sleeve to make a swing motion around a fixed point The first step in learning how to adjust a cone crusher is understanding the principles in place that allow the cone crusher to do its job Based on the diagram above, we can identify the main parts of a cone crusher the feed opening, the concaves, the mantle and the sizing gapCone Crusher Principle Diagram The hydraulic cone crusher handles secondary crushing in the production line, and specializes in processing of mediumhard materials During the operation of the equipment, there will be problems such as tooth cracking, wear, jamming, and undercutting of the umbrella teeth, which will not only affect production, but also Cause direct or indirect economic lossesCrushing Principle, Gear Wear and Solution of Cone

Cone Crusher Operation Principle Crusher Mills, Cone

Cone Crusher, CS Cone crusher, Spring Cone Crusher – Kefid Spring cone crusher has the advantage of low operation costs, It is a highperformance cone crusher based on the principle of layer crushing and more crushing less Cone Crusher Lamination Crushing Principle What Is Lamination Crushing? When the solid raw materials are under some certain pressure, pressure distortion will occur And when the pressure reaches to a certain degree, the particles will breaks and cracks in the weakest place The concept of lamination crushing is that the crushing of rocks not Introduction Of Lamination Crushing Principle In Cone The basic operating principle of a cone crusher is shown in Figure 4 The properties, ie size distribution and quality parameters, of the product leaving the crusher are a result of the(PDF) Cone Crusher Performance ResearchGate

A Detailed Overview of Cone Crushers and What You

In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be exploring in more detail the Cone Crusher Crushing Characteristics And Working Principle Cone Crusher Crushing Characteristics And Working Principle 2019 6 1 Working Principle of Crushers View Larger Image On left is a showing of the standard gyratory with straight concaves is a section through any vertical radial plane in the crushing chamber ofWorking Principle Of A Cone Crushing Equipment The first step in learning how to adjust a cone crusher is understanding the principles in place that allow the cone crusher to do its job Based on the diagram above, we can identify the main parts of a cone crusher the feed opening, the concaves, the mantle and the sizing gapCone Crusher Principle Diagram

Working Priniciple Of Cone Crusher

What Is A Hydraulic Cone Crusher HongXing Machinery Dec 05 2019 Hydraulic cone crusher working principle When the cone crusher works the rotation of the motor is performed by a pulley or coupling the cone crusher transmission shaft and the crusher cone under the force of an eccentric sleeve to make a swing motion around a fixed point The hydraulic cone crusher handles secondary crushing in the production line, and specializes in processing of mediumhard materials During the operation of the equipment, there will be problems such as tooth cracking, wear, jamming, and undercutting of the umbrella teeth, which will not only affect production, but also Cause direct or indirect economic lossesCrushing Principle, Gear Wear and Solution of Cone CrusherPrinciple of Cone Crusher Cone crusher crushes materials by the working surface between the movable cone and fixed cone The movable cone of the cone crusher is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearingCone Crusher Fodamon Machinery

Working Principle Of A Symon Cone Crusher ulang

Working principle of cone crusher Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for Cone Crushers The Symons Cone Crusher has come into almost universal use during the last few years for the final stage of crushing It is a development of the secondary gyratory crusher, which is merely a small Cone Crusher Metallurgist Mineral Cone Crusher JXSC stone cone crusher machine is widely used in many sectors, such as mining, smelting, building materials, roads, railways, water conservancy, and chemical industries Our stone crushers machine is suitable Cone Crusher Mine Crushing Equipment JXSC

Working Principle Of A Cone Crushing Equipment

Cone Crusher Crushing Characteristics And Working Principle Cone Crusher Crushing Characteristics And Working Principle 2019 6 1 Working Principle of Crushers View Larger Image On left is a showing of the standard gyratory with straight concaves is a section through any vertical radial plane in the crushing chamber of The basic operating principle of a cone crusher is shown in Figure 4 The properties, ie size distribution and quality parameters, of the product leaving the crusher are a result of the(PDF) Cone Crusher Performance ResearchGate In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be exploring in more detail the A Detailed Overview of Cone Crushers and What You

- vertical y molino de bolas

- planta de procesamiento de grava de r o

- Transporte De Material Molino De Bolas Superfinos Flujo

- serie cs trituradora de no en sudáfrica

- trituradora de martillo usad

- molinos de martillos a la venta

- máquina rtadora de carne

- equipos de movimiento de tierra pesada

- proveedor de máquinas de cantera en kenia

- trituradora de mandíbula pequeña roca usados para la venta

- la máquina de pulir eléctrica fabricante de

- ste de molinos de bolas de arena

- mini amoladora pulgadas

- viviendas el calafate llave en mano

- nacl molino de martillos

- Molienda De Clínker Dibujo Molino

- tizacion de metales de tungsteno en londres

- precio de un molino de bolas para arcilla

- Utilizado Para La Fábrica De Cemento Mineral De Hierro

- tipo de trituradora en la industria del cemento

- molinos de bolas para la venta utilizó

- Excelente calidad chancadora de impacto precio

- sitios de trituradora de piedra en nashik

- molino de molienda para el fosfato de roca

- las perspectivas del mercado de martillo

- trituradora de piedras en uruguay

- prensas de cinta transportadora usadas

- trituraci oacute n del carbonato de calcio

- el uso de la trituradora de carbón

- roca para tritutra molienda