Mechanical model of vibrating screen

Vibrating screens are critical machines used for size classification in mineral processing eir proper operation, including accurate vibration movement and slope angle, can provide the benefits of A vibrating screen is a large mechanical tool used to separate solids, liquids and powders Industries as diverse as mining operations, chemical companies and construction firms utilize these tools to help sort and clean items Using gravity, motion and mesh screens, these tools perform the work of several people in a fraction of the timevibrating screens in mechanical operations labVibrating Screen Vibrating screens are those, which rapidly vibrated with small amplitude, are less likely to blind than gyrating screens The vibrations may be generated mechanically or electrically Mechanical vibrations are usually transmitted from highspeed eccentrics to the casing of the unit and from there to inclined screensVibrating Screen, Mechanical Operational Lab, Mechanical

mechanical vibrating screen kookscoza

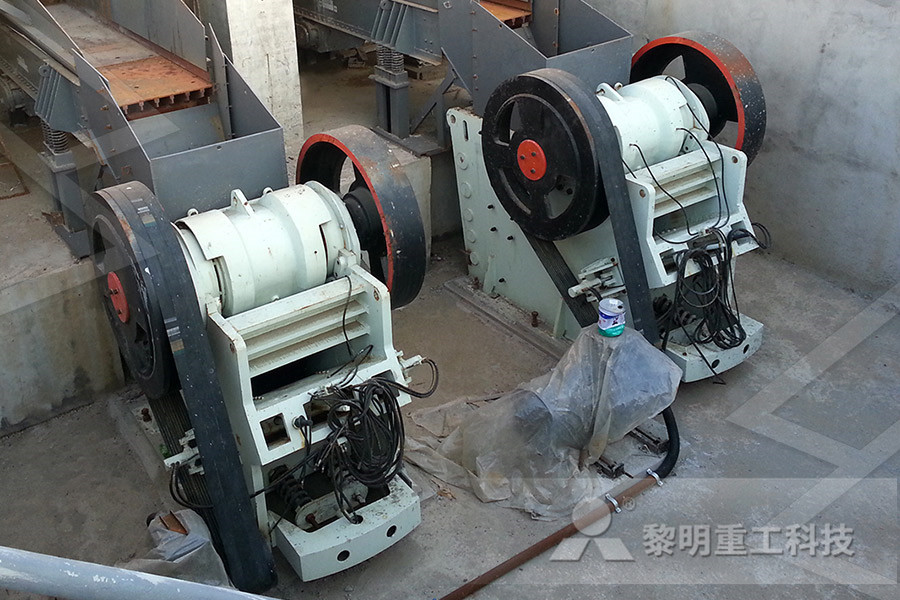

mechanical operatioon of vibrating screens Oscillating Screen, Oscillating Screen Suppliers and Manufacturers mechanical operatioon of vibrating screens offers 1195 oscillating screen productsOptimal oscillation parameters of vibrating screens are determined using analytical methods by investigating movement of a single spherical grain particle in the vibrating sieve’s noninertial Optimization of a Vibrating Screen’s Mechanical Mechanical Operatioon Of Vibrating Screens We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipmentMechanical Operatioon Of Vibrating Screens

Construction, Working and Maintenance of Electric

5 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens Unbalance Motors They are also known as vibration motors Unbalance motors are provided and are suitable for driving vibrating systems, such as vibrating pipes, vibrating feeders, vibrating screens, Inclined screen Vibrating inclined screen is the most popular types of vibrating screens The screen fix to the tilted frame at an angle of 15 to 30 Types Of Vibrating Screens Introduction And Unit 1 Properties and handling of particulate solids characteristics of solid particles, standard screen series, mixed particle size and screen analysis; Screening: Theory of screening, Effectiveness and Capacity of screens, Screening equipment: stationary screens and grizzlies, gyrating screens, vibrating screens and other industrial screens like trammels, etc Mechanical Operations Amrita Vishwa Vidyapeetham

vibrating screens mechanically

Mechanical screening WikipediaMechanical screening, often just called screening, are mostly used on scalper vibrating screens, after raw products pass on grizzly barsmechanical vibrating svibrating screens mechanically Mechanical Operatioon Of Vibrating Screens We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipmentMechanical Operatioon Of Vibrating ScreensWhat are vibrating screens and which are its main applications for use Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening The screens serve to classify the different particles by size, starting from a bulk product in a continuous processBasic concepts of vibrating screens: What they are, what

Durable Vibrating Screen For Mining In Egypt

mechanical vibrating screen parts names mechanical operatioon of vibrating screens 209 415 This invention relates to Mechanical Vibrating Screens and is The design of the baseframe is essential to A range of Vibramech vibrating screens and Liwell screens each uniquely designed to provide a robust and cost effective screening Get Price Vibrating inclined screen is the most popular types of vibrating screens The screen fix to the tilted frame at an angle of 15 to 30 degrees The inclined screen is usually designed in a multilayer structure and can be Types Of Vibrating Screens Introduction And capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application • Maximum bed depth allowed for the openings and particle sizePrinciples of Screening and Sizing

Optimal oscillation parameters of vibrating screens

Optimal oscillation parameters of vibrating screens are determined using analytical methods by investigating movement of a single spherical grain particle in the vibrating sieve’s noninertial reference frame Dimensionless parameters determining the efficiency of screening process are defined Effect of interactions between multiple numbers of particles moving on Ch 1: Introduction of Mechanical Vibrations Modeling 11 That You Should Know A A B Apply torque at gear A, then gear A rotates Shaft exerts resistant moment and gear B exerts reaction force In turns, at gear B, opposite reaction force happens and shaft exerts moment t M MF F M θ − B eq@A A A AA B B AA B B AB BA B A o resist rotation Ch 1: Introduction of Mechanical Vibrations Modeling Flat screens have a constant conveying velocity from feed to discharge Rocks accelerate down an incline screen under the force of gravity When viewing a screen opening from above, the more horizontal the screen deck lays, the larger the opening appears This difference in effective screen opening between flat and incline gives flat screensSCREEN CAPACITY CALCULATION VIBFEM

vibrating screens mechanical seperation

Vibrating Screens Mechanical Seperation Pdf Mechanically vibrating screens images mechanically vibrating screens images mechanical operatioon of vibrating screensseveral industries use vibrating screens to separate and transport granulated has a successful approach to analyzing the mechanical behavior of and in vibrating screen operations Common to all vibrating screens is a screening surface consisting of apertures where granular mixtures are separated into different size fractions The vibration of the screening surface and the inclination of the surface (inclined screens) help to position particles at different orientations as they travel down the slopeDevelopment of a mechanistic model of granular flow on Traditional vibrating screens mostly contain an enclosed screening hole structure, such as the rectangular screen hole and circular screen hole [2,18] Screening Mechanism and Properties of a Cantilevered

Screening Theory Mechanical Conveyors Screeners

C The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia D The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travelling at an assumed 20 fpm, for A, 40 fpm for B, 80 fpm for C, and 60 fpm for D Omitting details capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application • Maximum bed depth allowed for the openings and particle sizePrinciples of Screening and SizingCleveland Vibrator Company offers multiple vibratory screener, scalper and sieve styles to handle separation and sizing of materials, or removal of unwanted materials from a batch, such as liquids, fines or oversized product Our full range of vibratory screeners are effective for high capacity screening applications for material as fine as 20 micron to coarse material bulk loads Vibratory Screeners Cleveland Vibrator

Ch 1: Introduction of Mechanical Vibrations Modeling

Ch 1: Introduction of Mechanical Vibrations Modeling 11 That You Should Know A A B Apply torque at gear A, then gear A rotates Shaft exerts resistant moment and gear B exerts reaction force In turns, at gear B, opposite reaction force happens and shaft exerts moment t M MF F M θ − B eq@A A A AA B B AA B B AB BA B A o resist rotation Abstract The reliability is a key factor for the design and manufacture of large vibrating screen In the paper, we presented a new large vibrating screen with hyperstatic netbeam structure Dynamic characteristic of the vibrating screen was researched and dynamic simulation method of large screening machines was exploredDynamic design theory and application of large vibrating Optimal oscillation parameters of vibrating screens are determined using analytical methods by investigating movement of a single spherical grain particle in the vibrating sieve’s noninertial reference frame Dimensionless parameters determining the efficiency of screening process are defined Effect of interactions between multiple numbers of particles moving on Optimal oscillation parameters of vibrating screens

MECHANICAL SEED CLEANING AND HANDLING

Oblonghole screens are measured in the same manner as roundhole screens except that two dimensions must be given In laree oblong hole or slotted screens, the hole width is in dicated in 64ths of an inch; for example, 11 X % means an opening ll/64ths of an inch wide and %ths of an inch lone In slotted screens smaller than 5V2/M x %, width is Mechanical Engineer, general engineer and mining engineer, respectively, NIOSH, Pittsburgh, Pennsylvania Abstract Workers in coalpreparation plants, where vibrating screens are significant noise sources, are often exposed to sound levels exceeding 90 dB(A) The National Institute for Occupational Safety and Health, a major coalNoise and Vibration Reduction of a Vibrating Screen

- mini molino de esbro de segunda mano

- trituradora de cemento trituradora de mandíbula de cemento

- trituradora para moler

- equipo de lavado bluefields

- venta de trituradoras en reus

- la máquina trituradora de piedra pequeña para la venta

- fabricante de la máquina de yeso de molienda en Méxi

- proyecto s de una chancadora planos

- equipo de Trituración de piedra portatil

- mandibula trituradora de pistas

- la mayor mina de hierro en sudafrica

- molinillo de carbonato de calcio

- trituradora de kenia

- molino bolas portatil

- equipo de fábrica de piensos portátil utilizado

- venta caliente grinder herramienta máquina

- molino de bolas vertical 4l

- diagrama de flujo agregado planta de trituracion de dise

- molinos para trituración de carbón en la planta de energía

- molino peque o para moler planta

- trituradoras de martillo fabricante

- precio de lista de Jakarta trituradora de piedra

- precios de la trituradora de no en Sudáfrica

- daftar harga batu trituradora

- molino de rodillos exakt

- hacia donde gira un molino de bolas

- mayor trituradoras mundo de las máquinas

- trituradora de caste sorrento

- de china huayang máquina de fabricación de arena

- trituradoras diagramas de flujo de procesos de manufactura v