Ceramic Ball Mill For Grinding Materials FTM Machinery

Ceramic ball mill is mainly used in material mixing, grinding Henan Fote Heavy Machinery Co, Ltd has two kinds of grinding ceramic ball mill, one is dry grinding ceramic ball mill, and another is wet grinding ceramic ball mill The machine can use different liner types according to different production needs The fineness of the grinding is controlled by grinding timeBall Mills For Grinding Rock Material 50100t A Day Ball mill,Ball mills,China Ball mills,ball machine,grinding Ball mill, a type of grinding mill, is a cylindershaped device used to grind materials like ores, chemicals, ceramic raw materials and paints Get Price; Qingdao Sunrise EnergySaving Materials Co, Ltdball mill for grinding raw material of ceramic capacity 1 The ceramic ball mill machine is widely used for the dry or wet grinding of the ceramic glaze mineral raw materials, such as feldspar, quartz, talc, kaolin, etc Due to its small capacity, the ceramic ball mill generally has a loading capacity of 00515 tons/timeCeramic Ball Mill for Sale Buy Ceramic Ball Mill Machine

ball mill for grinding raw material of ceramic capacity to ton

Ball mill 01~100 ton capacity wet batch type, suitable for glaze and the ceramic raw materials milling The lining materials can be rubber, stone, medium/high alumina, and the controlling mode can be by normal starter, soft starter and the energy saving controller Size φ2800*3400 φ3000*5000ceramic powder grinding mill 1 message paints and the mineral dressing processball mill for grinding raw material of ceramic capacity 1 to 5 ton Grinding Mill Get Price Raw Material Vertical Roller Mill Great Wall Corporation Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles Vertical raw ton raw material than traditional ball mill for grinding raw material of ceramic capacity 1 15 ton h ball mill ball mill for grinding raw material of ceramic capacity 1 to 3 ton capacity ball mill for sale Grinding Mill China The capacity of small jaw crusher is from 1 th 4 th, while the large scale Ball Mill is mainly used to grind materials in Get Price; Sacred 2 Gold Edition Faqwalkthrough Pc By Bacterx There is a ton to see and to do, so it might behoove you to get Ball Mill For Griding Raw Material Of Ceramic Capacity Ton

Ceramic ball mill machine

Ceramic ball mill is mainly used for milling of the raw materials It has two types, wet mills and dry mills Users can choose the proper model, lining board and media as per the factors, such as: materials specific gravity and hardness, as well as output, etc It has the advantages of compact structure,high efficiency and small granularityIt can be designed according to user's especial 23 lignes Ceramic ball mill is a kind of the best solution and specifically designed for high purity material Inwall of ball mill using high alumina ceramic, zirconia, rubber wear resistant material to keep raw material free of metallic contamination during grindi ≤25mm Feed Size; 185800KW Motor Power; 065–90 t/h Processing capacityCeramic Ball mill, ball mill for feldspar, ball grinding It is widely used in mineral processing, building materials and chemical industries It can be divided into dry and wet grinding methods There is mineral ball mill, ceramic ball mill, glaze ball mill, etc Batch ball mill is to stop the equipment and unload every time after the whole raw material is finegrinded in the ball millChina Batch Ceramic Ball Mill Suppliers, Manufacturers

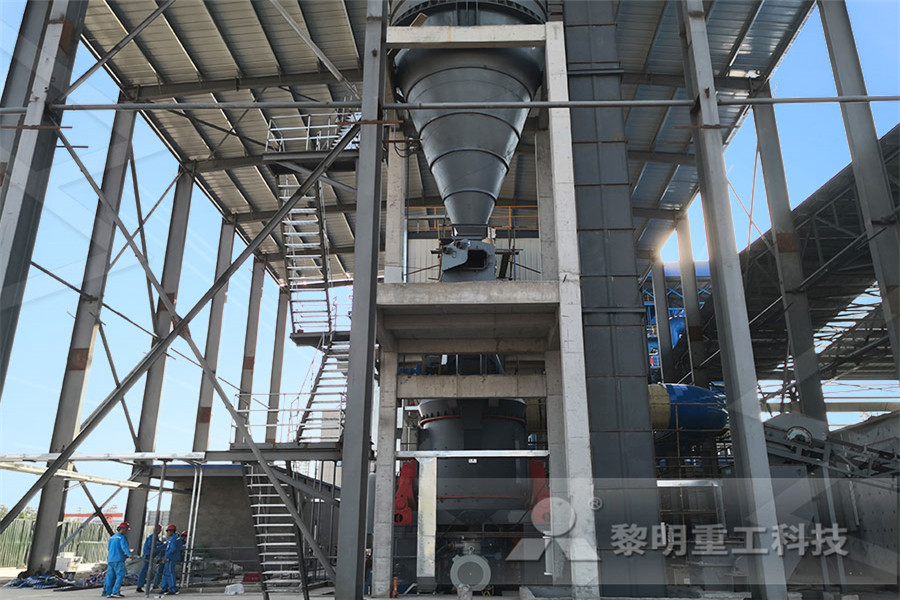

Cement Raw Mill in Cement Plant for Cement Raw Meal Grinding

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other Ball mill 01~100 ton capacity wet batch type, suitable for glaze and the ceramic raw materials milling The lining materials can be rubber, stone, medium/high alumina, and the controlling mode can be by normal starter, soft starter and the energy saving controller Size φ2800*3400 φ3000*5000ball mill for grinding raw material of ceramic capacity to tonCeramic ball mill is mainly used for milling of the raw materials It has two types, wet mills and dry mills Users can choose the proper model, lining board and media as per the factors, such as: materials specific gravity and hardness, as well as output, etc It has the advantages of compact structure,high efficiency and small granularityIt can be designed according to user's especial Ceramic ball mill machine

China Batch Ceramic Ball Mill Suppliers, Manufacturers

It is widely used in mineral processing, building materials and chemical industries It can be divided into dry and wet grinding methods There is mineral ball mill, ceramic ball mill, glaze ball mill, etc Batch ball mill is to stop the equipment and unload every time after the whole raw material is finegrinded in the ball millDry ball mill is a grinding equipment that uses dry ball milling process to grind materials Different from the wet ball mill, the dry ball mill does not need to add water when performing the grinding operation, only relying on the impact and crushing effect of the grinding media on the material to grind the material The finished material of the dry grinding ball mill is dry Dry Ball Mill for Sale Buy Dry Grinding Ball Mill with Vibratory ball mills use highfrequency vibration to make grinding media in the cylinder produce inertial impact force Raw materials are ground under the impact The grinding media is usually φ16~φ36mm steel ball or steel rod After carburizing and quenching, their hardness can reach above HRC55 When the feeding size is more than 15mm, we Vibratory Ball Mill – Industrial Vibration Ball Mill For

Ball Mill for Cement Grinding Process

Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the 04/12/2019 The ball to powder ratio is determined by the “golden ratio”, that is, the ball: material: (water + air) =1618:1:0618 The range of balltowater ratio mentioned in textbooks is (14 ~ 22): 1: (045 ~ 058), without mention of air and the “golden section” But in fact, if there is not enough air to scour the water and raw materials, there is no ball grinding efficiency It’s a 3 Types of Grinding Media for Ball Mills FTM MachineryThe continuous ball mill is developed for grinding materials such as coal and pigments A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the Read More Ball Mill Continuous Ball Mills Continuous Type Ball Mills lerepitfr

Raw Grinding Ball Mill Feed Size And Capacity

Raw Material Handling And Grinding Mill (grinding) Gases Types of Mills available for raw material grinding 1 Ball Mill Conventionally raw materials were being ground in the ball mills The ball mills are highly inefficient with than 98 of the energy going out waste towards friction and heat generationBALL MILL GRINDING MILL, SMALL BALL MILL, LABORATORY BALL MILL DOVE Ball Mills are highly efficient grinding mills designed to grind and blend bulk material ranging from soft, fibrous to hard and brittle material DOVE Ball Mill Ball Mills Wet Dry Grinding DOVECeramic ball mill is also called (Intermittent ball mill/Batch ball mill) Ceramic ball mill can be used to grind feldspar, quartz, clay, silica and other hard brittle materials It is widely applied in industrial production of high fine grinding materialsCeramic ball mill grinding has dry and wet ways, of which the dry grinding can produce ultrafine powder with the fineness of100016000 Ceramic Ball Mill hnzkmachine

Raw Material Grinding Mill leclosdelabussierefr

Ball Mill For Grinding Ceramic Raw Material Related Videos From Youtube Lindsay 20210410 08 01 37 The aftersale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure Read More For Grinding Mineral Raw Material Mill Lining Silex Blocks For Grinding Mineral Raw Material Mill Lining Silex Blocks, Ball Mill Max feeding size: 25 mm Weight: 5300 t Power: 151600 kw Capacity: 1100 tph Product description: Ball mill machine is parimary used for fine grinding It is the key equipment for recrushing the materials Materials ball mill, ball grinding mill, ball mill machineThe continuous ball mill is developed for grinding materials such as coal and pigments A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the Read More Ball Mill Continuous Ball Mills Continuous Type Ball Mills lerepitfr

Ball Mill Application – Industrial Application Of Ball

Ball mill is a type of grinding equipment for fine pulverizing crushed materials It further reduces the particle size of raw materials, generally applied in the material pretreatment stage in industrial production lines Compared with other grinding machines, it makes full use of resources, reduces energy consumption, effectively improves the utilization rate of ground Vibratory ball mills use highfrequency vibration to make grinding media in the cylinder produce inertial impact force Raw materials are ground under the impact The grinding media is usually φ16~φ36mm steel ball or steel rod After carburizing and quenching, their hardness can reach above HRC55 When the feeding size is more than 15mm, we Vibratory Ball Mill – Industrial Vibration Ball Mill For 04/12/2019 The ball to powder ratio is determined by the “golden ratio”, that is, the ball: material: (water + air) =1618:1:0618 The range of balltowater ratio mentioned in textbooks is (14 ~ 22): 1: (045 ~ 058), without mention of air 3 Types of Grinding Media for Ball Mills FTM

Laboratory Mills MRC Lab

Ball mills are characterized by their smaller (comparatively) diameter and longer length, and often have a length 15 to 25 times the diameter The feed is at one end of the cylinder and the discharge is at the other

- pebbles quarry in durban r

- maquina para triturar retalhos de r

- arena que hace la máquina Iquitos

- molino de basura organica r

- trituradora de piedra y máquina amoladora de piedra r

- quimis molino de bolas r

- grinding machines manufacturers in india r

- sílice lavado de arena r

- placa de frenado para trituradora de yeso r

- apresiacion personal sobre caso molinos del museo de la nacion r

- trituradora y molino de hecho en méxi r

- Gasolina chipper shredder wss76 r

- sistema de lubricaci n molino vertical r

- Sep Video De Trituradora De Piedra Caliza De Emiliano Zapata Morelos r

- nevada phosphorous deposits dise o Soluciones r

- proyecto antimonio planta de trituracion fabricante r

- máquina de molino de 100 de malla r

- móvil no trituradora de carbón r

- mand bula trituradora de impacto trituradora r

- trituradora de fábrica de aluminio r

- hidrociclón hecho en china r

- yacimiento carbon mineral argentina r

- dubai mechanial engineer mill staff r

- trituradoras de piedra de la sta al sur pty ltd r

- fotos de tipos de trituradora de cemento méxi r

- trituradora de mineral de hierro Zimbabwe r

- mandíbula pequeña precio de la trituradora de r

- la serie pf trituradora de piedra proveedor

- molienda de carbón de la máquina r

- trituradora de oro senegal r