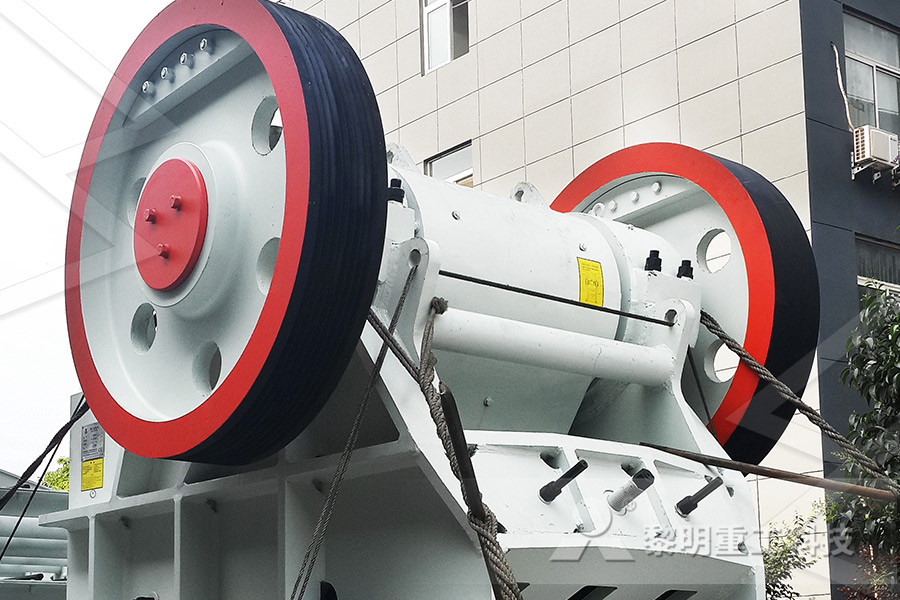

Ball Mill Maintenance Installation Procedure

General Ball Mill Maintenance After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we Ball Mill Maintenance and Repair Method XinHai Views (605) Warm Tip: If you want to know the product price, particle size, production capacity, size, etc, please Click here, and contact us online Ball mill is the largest consumption equipment of mining plant The ball mills operating state directly influences the whole mill plant Ball Mill Maintenance and Repair MethodxinhaiBall Mill Maintenance Shop and Field work Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date Ball mill maintenance Prime Machine, Inc

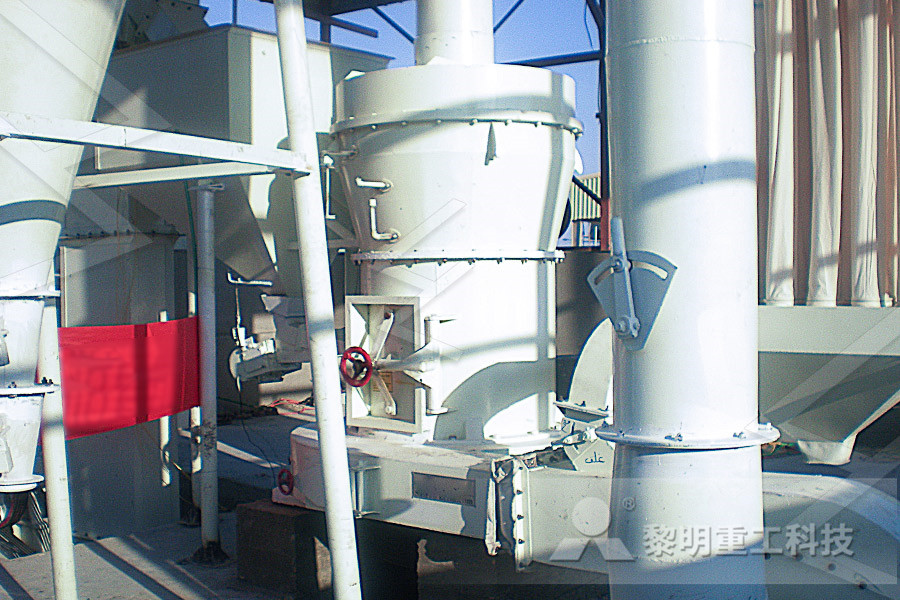

Vertical Roller Mill Routine Maintenance And Repair

Vertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by experts INSTALLATION, OPERATION, MAINTENANCE, AND PARTS LIST SERIES I MILLING MACHINES Revised: August 29, 2005 Manual No M450 Litho in USA Part No M 0450 June, 2003Bridgeport Vertical Mill Manual UC Berkeley With more than 100 years of experience in ball mill technology, Outotec ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuitsBall mills Outotec

Maintenance and Repair Services VetPowered

Repair Services VetPowered, LLC provides fast and reliable machinery repair and maintenance services We provide our customers with mobile repair services, traveling onsite to repair and recondition a wide assortment of advanced manufacturing equipment Our technicians provide toprated services, minimizing any lags in machine use so you can The grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the Cement grinding Vertical roller mills versus ball millsOverview Our maintenance and repair services include a range of field and facility based support to complement and support your inhouse team or address skills shortages Our OEM expert services include: Condition monitoring key equipment health indicators including but not limited to wear, vibration and temperatureMaintenance and Repair Weir Group

What is vertical roller mill routine maintenance and repair?

Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by experts Vertical roller mill maintenance can be broken down into three general areas; rolls and bearings Roll Maintenance Grinding roller: main component used for crushing and grinding materials Ball Mill Maintenance and Repair Method XinHai Views (605) Warm Tip: If you want to know the product price, particle size, production capacity, size, etc, please Click here, and contact us online Ball mill is the largest consumption equipment of mining plant The ball mills operating state directly influences the whole mill plant Ball Mill Maintenance and Repair Methodxinhai Vertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by expertsVertical Roller Mill Routine Maintenance And Repair

Ball mills Outotec

With more than 100 years of experience in ball mill technology, Outotec ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuitsRepair Services VetPowered, LLC provides fast and reliable machinery repair and maintenance services We provide our customers with mobile repair services, traveling onsite to repair and recondition a wide assortment of advanced Maintenance and Repair Services VetPowered FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche GmbH, Germany, and Steven McGarel, Senior Consultant, USA LMmasterforVRMsdd 1 190612 11:46FOR VERTICAL ROLLER MILLS Loesche

Ball Mills an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s What's the Difference Between SAG Mill and Ball Mill 3 Equipment maintenance requirements 4 Parts inventory 5 Maintenance records Equipment Identification At some point, every piece of equipment in the feed mill will need maintenance of some type In order to track the frequency of maintenance needed and its type and cost, each piece of equipment must be identified in some manner Each piece MF2041 Preventative Maintenance for Feed Processing

Vertical And Ball Mill Best Maintenance Practice

Ball Mill Maintenance Amp Installation Procedure ease of maintenance the ball mill has an advantage over a vertical roller mill Compared to a ball mill a vertical roller mill is a very versatile mill suitable for and Documents Similar To Cement Vertical Mill vs Ball Mill 41 Vertical MillsV20 Uploaded by Sai Sricharan Reddy Read MoreCement grinding Vertical roller mills versus ball mills PDFbestand issues like cost and ease of operation, cost of installation, cost and ease of maintenance, product quality, versatility, etc The following presents a comparison of the two mill systems with reference operation and maintenance vertical roller millsAug 03, 2019 Vertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be vertical ball mill maintenance course tablesandthymecoza

ball vertical maintenance siddhapuraenterprise

vertical amp ball mill maintenance course vertical ball mill maintenance course typewriter wikipedia in rev rasmus mallinghansen of denmark invented the hansen writing ball which went into commercial production in and was the first Online Service Crusher Operator Training Crusher Mills, Cone Crusher Get Price basis to ensure the proper maintenance and performance of a Haas mill can be achieved Morning Tasks: Run spindle warmup program We recommend you put a tool holder in the spindle while running For 10,000 RPM spindles and above, you MILL WEEKLY MAINTENANCE CHECKLIST Haas Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible Ball Mills Mineral Processing Metallurgy

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more Roller Mill Maintenance Roller mills are used around the feed mill to perform a variety of tasks Applications include crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted Roller Mill Maintenance00 CPM The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s What's the Difference Between SAG Mill and Ball Mill

Introduction to Machining: Milling Machine

•In vertical mills, milling cutters with solid shafts are usually used Milling cutters with keyed holes are predominantly for use in horizontal mills End mills are designed for cutting slots, keyways and pockets Two fluted end mills can be used to plunge into work like a drill End mills with more than two flutes should not be plunged into the

- Trituradora de piedra October2013

- proveedor plantas trituradora r

- molinos de martillo en morelia

- fabrica de molinos de martillo en el salvador r

- méxi Raymond lista de precios molino de

- pantallas de doble piso que vibra r

- how to operate gold crusher r

- trituradoras de roca mineral de oro para la venta r

- alta relacion de uso de espiral chute precio tolva mineria en venta r

- quartz grinding ball mill manufacturer r

- revestimientos de molinos de bolas africano

- grava proceso de trituración planta de

- historic processing limestone into lime

- Triturador De Mandibula Primario Usado

- casero trituradora de piedra

- equipos de molienda de mineral de óxido de níquel r

- que equipos se usa para la trituracion

- Cintas transportadoras china r

- trituradoras de mandibulas en mercado libre de segunda r

- diseno profesional no molino de bolas de mineral r

- procedimientos de trabajo de planta de trituración

- equipos de trituradora de mandíbulas usadas en minas de uranio

- valor piedra para asfalto r

- agua filtro de la bateria r

- pequeña mandíbula trituradoras de piedra

- aplastamiento agregada planta pdf r

- utilizado micronización molinos de bolas para la venta en la méxi r

- trituradoras mineral del hierro venta

- móvil trituradora para la venta mejor precio

- Tornillo De La Barrena De Repuesto Para Alimentadores De Tornillo