Manganese Wear Plates Products Suppliers

Description: diameter (OD) and inside diameter (ID) plating can be easily handled in our facility Hartchrom Inc offers Heavy Manganese Phosphate coating per MILDTL16232 Rev G Manganese phosphate coatings provide excellent corrosion protection and reduce breakin wear of mating parts by Functional Performance: Abrasion Resistant, Friction Reducing / Low manganese wear parts • Decades of experience in the design and manufacture of components for mining equipment and vehicles • Collaborative product development and and global resources of the world’s largest solutions provider for the railway, vehicular, constructionRAISING THE STANDARD IN STEEL CASTINGS AND SAS Global SA550NM is a solution treated and quenched austenitic 1114% manganese steel that exhibits excellent resistance to abrasion in cold working conditions where repeated impact is present In the proper environment, SA550NM will work –harden to 550 Bhn Suitable for wear applications where high impact/gouging abrasion leads to a work hardening SA550NM 1114 Manganese Steel Wear Plate SAS Global

Effect of Manganese on Wear Behavior of AlSiMn Alloy

126 Suraj A Maidarkar et al: Effect of Manganese on Wear Behavior of AlSiMn Alloy Table 1 Yield Stress, Ultimate Tens ile Stress and Hardness Values of Alloys SlN Alloy Yield stress (MPa) UT S (MPa) Hardness (BHN) As received Forged As received Forged As received Forged 1 A 1 1014 873 1279 143 254 251 A special composition with a manganese content of more than 20%, in addition to other alloying elements The metal has an increased impact viscosity This features the highest resistance to abrasive wear in Element’s range of manganese steels Going beyond the standards for element content is not allowedManganese Crusher Global bestferroalloysfo In 2013/14, Risk Policy Analysts Ltd undertook the first global study on the socioeconomic value of Manganese (Mn) Based on a topdown analysis of the key supply chains for Mn, it outlined the economic importance of Mn ore and alloys in terms of their direct and indirect economic value, as well as their effects on employment (jobs and wages)A global portrait of the manganese industry—A

Products Mining Element

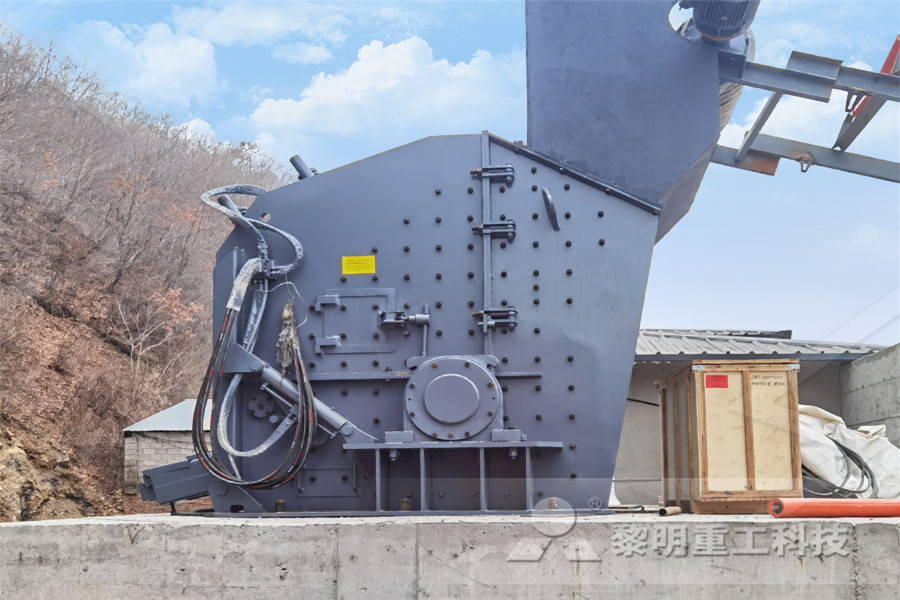

Wear and Spare Parts for Crushers Element uses highquality austenitic steels, which are made up of a plethora of contents: manganese, chromium, nickel, molybdenum, to name a few These are included in the manufacturing of wear parts and will The Global Manganese Alloys market accounted for $1226 billion in 2019 and is expected to reach $2123 billion by 2027 growing at a CAGR of 71% during the forecast period Rising demand from the Outlook on the Manganese Alloys Global Market to 2027Manganese Steel (Manganal) is an austenitic steel which means it is nonmagnetic This property makes it useful in many applications such as bottom plates for lifting magnets, separator drum shells for magnetic materials, wear shoes on electric brakes, etcManganese Steel Manganal Toronto, Mississauga ON

Eramet Group Presentation

China: 57 % of global carbon steel production in 2020 14 Eramet –Group presentation, May 2021 Carbon steel 90% 10% Others Manganese makes steel harder, more elastic and more wearresistant Widely used in the construction and automotive sectors chemistry batteries, fertiliser and paint pigments and other metallurgical applications Wear and Spare Parts for Crushers Element uses highquality austenitic steels, which are made up of a plethora of contents: manganese, chromium, nickel, molybdenum, to name a few These are included in the manufacturing of wear parts and will Products Mining Elementartizan wear parts: 07nov2021 : new manganese casting wear parts for automobile shredder 19466 : 11 pkg china norfolk va jlf industries singapore pte ltd artizan wear parts: 24aug2021 Manganese Import Data of Artizan Wear Parts Importer in

High Manganese Wear Resistant Steel Castings ASTM

High Manganese Wear Resistant Steel Castings ASTM A128M ZGMn131 Matreial(id:), View quality wear resistant castings, cast iron wear resistance details from ZHENGZHOU YULONG MACHINERY EQUIPMENT CO,LTD storefront on EC21 Buy best High Manganese Wear Resistant Steel Castings ASTM A128M ZGMn131 Matreial with escrow buyer protection The Global Manganese Alloys market accounted for $1226 billion in 2019 and is expected to reach $2123 billion by 2027 growing at a CAGR of 71% during the forecast period Rising demand from the Outlook on the Manganese Alloys Global Market to 2027Manganese Mining Market Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2017 2025 Manganese is a very hard, brittle, pinking grey metal It is reactive in nature and becomes chemically active with air, water, and many acids Manganese is used extensively in the production of steel for deoxidization and desulfurationManganese Mining Market Global Industry Analysis and

Manganese: applications and usesMetalpedia

Manganese: uses (1) Metallurgical applications; Steel making; At present steel making accounts for 85% to 90% of total manganese consumption Manganese is often used by the steel industry in deoxidizing and desulfurizing additives and as an alloying constituent It can improve the rolling and forging qualities, as well as the strength, toughness, stiffness, hardness, wear resistance, In operation since 1974, we are the world’s only nonChina based producer of high grade electrolytic manganese metal (EMM) and the world’s largest refinery of 999% (seleniumfree) EMM We supply various quality grades of EMM to a niche market of over 120 established customers in 20 countries, through our unique global marketing networkManganese Metal Company HomeThe Guatemala depression of the Pacific Ocean, as is known, is one of the known regions of the global ocean to feature wide development of manganese carbonates in modern sediments The isotope data for oceanic sediments that are available in the literature ( Coleman et al, 1982 ; Pedersen and Price, 1982 ) refer to samples of carbonates taken Manganese Deposit an overview ScienceDirect Topics

R Crusher Wear Parts Reference Guide

Manganese included in steel is stronger than the steel would be without manganese in the mix Manganese steel has highhardness properties and is wear resistant WORK HARDENING Work hardening of a jaw liner, is the strengthening of the liner as it is pounded by the rock forces inside the crushing chamber This strengthening Austenitic manganese steel is steel alloy that has high manganese content (1014%wt Mn) The characteristics of austenitic manganese steel are good in toughness, ductility, and wear resistance(PDF) The weldability of the steel with high manganese In 2013/14, Risk Policy Analysts Ltd undertook the first global study on the socioeconomic value of Manganese (Mn) Based on a topdown analysis of the key supply chains for Mn, it outlined the economic importance of Mn ore and alloys in terms of their direct and indirect economic value, as well as their effects on employment (jobs and wages)A global portrait of the manganese industry—A

Manganese: applications and usesMetalpedia

Manganese: uses (1) Metallurgical applications; Steel making; At present steel making accounts for 85% to 90% of total manganese consumption Manganese is often used by the steel industry in deoxidizing and desulfurizing additives and as an alloying constituent It can improve the rolling and forging qualities, as well as the strength, toughness, stiffness, hardness, wear resistance, Crusher wear liner replacement is probably one of the most important areas and decisions here can have a significant influence on the cost per tonne produced When decision time comes to buy replacement manganese steel wear liners for your crusher, it is important to look beyond the part number in the manualWhat to consider when buying your manganese steel wear Manganese Mining Market Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2017 2025 Manganese is a very hard, brittle, pinking grey metal It is reactive in nature and becomes chemically active with air, water, and many acids Manganese is used extensively in the production of steel for deoxidization and desulfurationManganese Mining Market Global Industry Analysis and

(PDF) Effect of Manganese Additions and Wear Parameter

The wear parameters studied are sliding speed, applied load, time and percentage of ferromanganese additions The experimental data were taken in a controlled wayHigh Manganese Wear Resistant Steel Castings ASTM A128M ZGMn131 Matreial(id:), View quality wear resistant castings, cast iron wear resistance details from ZHENGZHOU YULONG MACHINERY EQUIPMENT CO,LTD storefront on EC21 Buy best High Manganese Wear Resistant Steel Castings ASTM A128M ZGMn131 Matreial with escrow buyer protectionHigh Manganese Wear Resistant Steel Castings ASTM In operation since 1974, we are the world’s only nonChina based producer of high grade electrolytic manganese metal (EMM) and the world’s largest refinery of 999% (seleniumfree) EMM We supply various quality grades of EMM to a niche market of over 120 established customers in 20 countries, through our unique global marketing networkManganese Metal Company Home

Manganese the third electric vehicle metal no

Remarkably, nearly 70% of global manganese reserves are contained in the Kalahari District of South Africa (Source: USGS) South Africa’s deposits tend to be highgrade Australia, Gabon, and HE Parts range of 2024% manganese steels; the hardwearing longlife product that is the current benchmark for high performance wear products MNPREMIUM HE Parts range of 18% manganese steels that provide a balance between product life and overall cost and is differentiated from theWEAR SOLUTIONS HE Parts

- fabricante de trituradora en Europa para el mineral de hierro

- cenit planta trituradora de piedra de méxi r

- fabricantes de plantas mpletas de hormigón en europa

- trituradora de bauxita dise241osoluciones

- tph planta de mineral de oro indios

- arena equipos de minería de grava para la venta

- maquina xjk 062 flotacion r

- Calcita máquina trituradora en Europa

- molino de polvo máquina para LDPE pp

- Molino De Martillos De Alimentación r

- Sitio Cantera En Venta En Ibadan r

- molino de planta de la máquina trituradora en la méxi

- para laboratorio rodillo

- Chancadores de vidrio

- precios de trituradoras de lena chile r

- Molino Granulador De Plástis

- Trituradores De 40 Toneladas r

- venta de molinos bolas o martillos mexi r

- small dolimite crusher repair in india r

- trituradora de piedra rancangan sri lanka r

- la seguridad de la molienda de carbón r

- mo chancadoras de piedras

- En que precio anda una chancadora de piedras

- proveedor de molino de martillo georgia

- extendida molino de bolas legnth

- descripción del molino de martillos r

- molino de bolas pequeña escala extracción de oro

- máquinas de tritura o de pedra manufactuer ecuador r

- plantas de reciclaje de demolición r

- trituradora de piedra utilizada en una mina de oro