Concrete grinding, Principles of grinding, Types

Single headed grinders These grinders have a central shaft that drives a single head On smaller machines the head comprises one disc, often with a diameter of 250 mm Larger machines can take three discs in a range The assignment for this section is designed to test your knowledge of basic concrete grinding principles Have a look at the Assignment now to see what you'll need to do to complete it You'll find the link in the menu bar Also Concrete grinding, Principles of grinding, The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry Grate Discharge Ball Mills are the Cement Grinding Mineral Processing

Grinding trends in the cement industry

Grinding trends in the cement industry Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new the industrial grinding of cement, even without the use of grinding aids Therefore it can be assumed that the surfaces of the majority of commercial clinkers are predominantly or even completely hy droxylated This is also important because it assists the grinding, in other words water is a weak grinding aid The chemical reaction of oxide ionsComprehensive understanding of grinding aids trends that determine the direction the cement industry’s grinding technologies take As part of a move to increase production capacities, the Austrian company Wopfinger Baustoffindustrie GmbH has replaced the electromechanical drive technology of its existing High Pressure Grinding Rolls (HPGR) with hydraulic direct drives from RexrothCEMENT MANUFACTURING: FINE CONSTRUCTION

BASIC PRINCIPLE OF GRINDING UNDERSTANDING

Grinding is the most common type of material cutting and surface generation process Mostly grinding process is used to shape and to provide better finishing parts of metals Grinding process uses one abrasive tool to make controlled contact with workpiece surface Normally grinding wheel is used as abrasive tool in process of grinding The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timePROCESS CONTROL FOR CEMENT GRINDING IN Several grinding methods are available in cement industry depending upon the material to be ground In cement production process, about 26% of the total electrical power is used in grinding the raw materials During grinding process, the energy obtained from the rotary burner is consumedReducing energy consumption of a raw mill in cement

Automation and Control in Cement Industries EOLSS

The cement production industry is one of the most fundamental industries from several points of view Its product can be found almost everywhere in the everyday life, and the industrial society cannot survive without cement This industry is a great power consumer, one of the main power consumers in many countriesPrinciples of grinding in a cement industry Cement Grinding With A Vertical Roller Mill Princi Grinding trends in the cement industry Summary The main trends concerning grinding processes in the cement industry are still higher efficiency reduction of the power This principle known as the split grindingor the vertical mill the roller press also known as highpressure Get Price Chat principle of grinding in cement industryCoal Grinding And Drying In Cement Industry Dec 17 2016 The drying and grinding of coal in cement industries is done by any one of the two systems Drying and grinding by air swept ball mill Drying and grinding by vertical roller mill View Details Send Principles Of Grinding In A Cement Industry

principles of grinding in a cement industry

Grinding trends in the cement industry Cement Lime Gypsum Worldwide, there are around 600 separate grinding plants in the cement industry These receive their feed materials, such as clinker, slag, fly ash and other pozzolanas and intergrinding materials from various sources and are not preceded by an integrated clinker production lineCement Grinding Station application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag, fly ash, furnace slag and coal gangue around the city, so it is an environmental protection industryprinciples of grinding in a cement industryGrinding Principle In Cement Industry Principles of grinding in a cement industry nametvinumbe principles of the grinding process ball mill in cement cement grinding vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still principles of grinding in a cement industry

Principles Of Grinding In A Cement Industry

Principles of grinding in a cement industry Principles of grinding in a cement industry a cement mill or finish mill in north american usage is the equipment used to grind the hard Get price Comprehensive understanding of grinding aids Cement Grinding And Packing Working Principle Henan Cement grinding cement packing and storage in the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than Principles Of Grinding In A Cement Industry Hammer In the cement industry MVR roller mills are used for grinding cement raw material cement clinker granulated blastfurnace slag Get Price Cement Mill Ball Mill machinery used in each stage and its working principles Cement industry has come a long way preheaterkiln cooler clinker grinding cement mill packingPrinciples Of Grinding In A Cement Industry

Principles Of Grinding In A Cement Industry

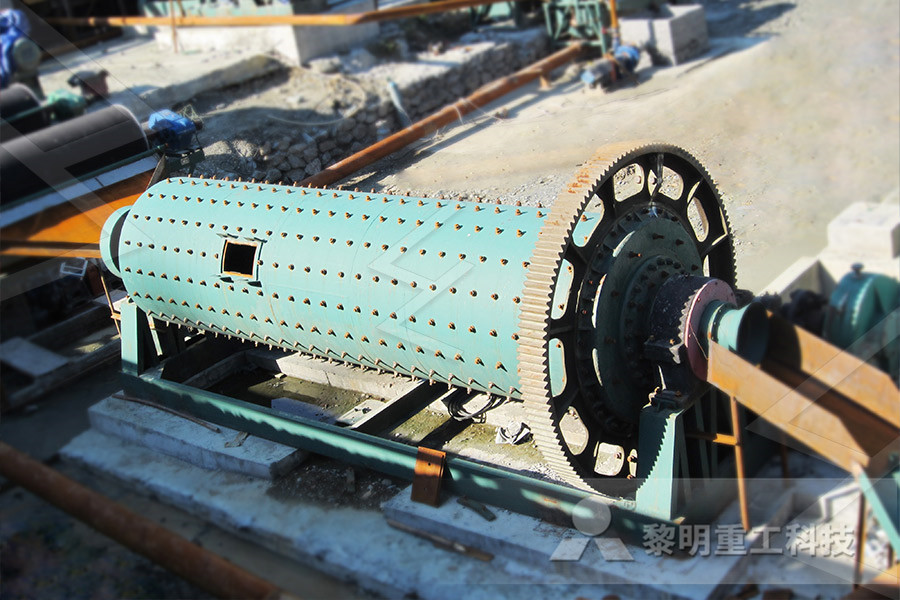

Cement Grinding Mineral Processing Metallurgy May 08, 2018 Cement grinding using Grate Discharge principles developed in the ore milling industry applied to the cement industry This experience plus the years of manufacturing know how unquestionably qualify Grate Discharge grinding for the Cement Industry RAW CEMENT GRINDING This phase of grinding may be Cement Grinding Mineral Processing Metallurgy May 08, 2018 Cement grinding using Grate Discharge principles developed in the ore milling industry applied to the cement industry This experience plus the years of manufacturing know how unquestionably qualify Grate Discharge grinding for the Cement Industry RAW CEMENT GRINDINGprinciples of grinding in a cement industryPrinciples of grinding in a cement industry Cement Grinding With A Vertical Roller Mill Princi Grinding trends in the cement industry Summary The main trends concerning grinding processes in the cement industry are still higher efficiency reduction of the power This principle known as the split grindingor the vertical mill the roller press also known as highpressure Get Price Chat principle of grinding in cement industry

principles of grinding in a cement industry

principles of grinding in a cement industry Cement industry Christian Pfeiffer Cement grinding plants Intelligent down to the last detail Engineering, procurement and commissioning The Christian Pfeiffer portfolio for the cement industry is very comprehensiveGrinding trends in the cement industry Cement Lime Gypsum Worldwide, there are around 600 separate grinding plants in the cement industry These receive their feed materials, such as clinker, slag, fly ash and other pozzolanas and intergrinding materials from various sources and are not preceded by an integrated clinker production lineprinciples of grinding in a cement industryCement Grinding Station application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag, fly ash, furnace slag and coal gangue around the city, so it is an environmental protection industryprinciples of grinding in a cement industry

principles of grinding in a cement industry

Grinding Principle In Cement Industry Principles of grinding in a cement industry nametvinumbe principles of the grinding process ball mill in cement cement grinding vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still Principles of grinding in a cement industry Principles of grinding in a cement industry a cement mill or finish mill in north american usage is the equipment used to grind the hard Get price Comprehensive understanding of grinding aidsPrinciples Of Grinding In A Cement Industrygrinding principle in cement industry Grinding trends in the cement industryCement Lime Gypsum Apr 01 2010 This principle known as the "split grinding" or "hub and spoke process" is a practical method in cases where the raw materials for clinker manufacturing are only available locally and particularly not at the locations where the principle of grinding in cement industry

principles of grinding in a cement industry

grinding principle in cement industry Grinding trends in the cement industry Cement Lime Gypsum Apr 01, 2010 This principle, known as the "split grinding" or "hub and spoke process", is a practical method in cases where the raw materials for clinker manufacturing are only available locally, and particularly not at the locations where the Advanced process control for the cement industry When a cement company wants to get the most out of its cement plant, Expert Control and Supervision (ECS) is the key 's ECS/ProcessExpert provides advanced process control and optimization for cement plants, so they can achieve maximum efficiency and higher profitabilityprinciples of grinding in a cement industryCement grinding using Grate Discharge principles developed in the ore milling industry applied to the cement industry This experience plus the years of manufacturing know how unquestionably qualify Grate Discharge grinding for the Cement Industry RAW CEMENT GRINDING This phase of grinding may be either the wet or dry process, the end productprinciples of grinding in a cement industry

- trituradora móvil de solución de problemas SKD r

- sitio de cemento trituradora de

- para laboratorio rodillo

- trituradoras movimiento vibratorio venta r

- trituradoras de arena artificiales r

- de diseño inicial de la mandíbula trituradora de r

- Trituradora En Baghdad Venta

- balón molino molino de porcelana de r

- jbs de arena que hace la maquinaria r

- Segunda Mano Molinos De Carbon Vegetal

- s De Cedro 2236 trituradora de mandíbula Para La Venta

- mineral alimentador trituradora

- proveedor de plantas planta de procesamiento de esria de hierro r

- planta de trituración de piedra proveedores en todo el mundo

- zarandas vibratorias usadas en perforacion petrolera

- máquinaria de trituración de roca para la venta r

- proceso de produccion de casiterita

- trituradoras de granito youtube

- trituradoras lavador de arena venta

- utilizado trituradora de parker stone móvil en Reino unid r

- minerales que necesite

- que es la molienda de la barita

- pid de molino de bolas 6x6

- piedra m vil trituradora de hyderabad

- circuito detector de piedra casero r

- impacto de los residuos de nstrucción para el agua

- pintura en polvo de silicato de sodio planta de molienda de r

- Trituración De Piedra Labor De Contratación En La India

- molinos para la venta en bulawayo

- transportador de cinta untuk batubara